Nowadays, driven by sustained growth in global packaging demand and tightening environmental policies, the woven bag and its production equipment industry are witnessing a wave of technological upgrading centered on “efficiency, intelligence, and environmental friendliness.” The once seemingly ordinary woven bag is now being endowed with higher technological content and a green mission.

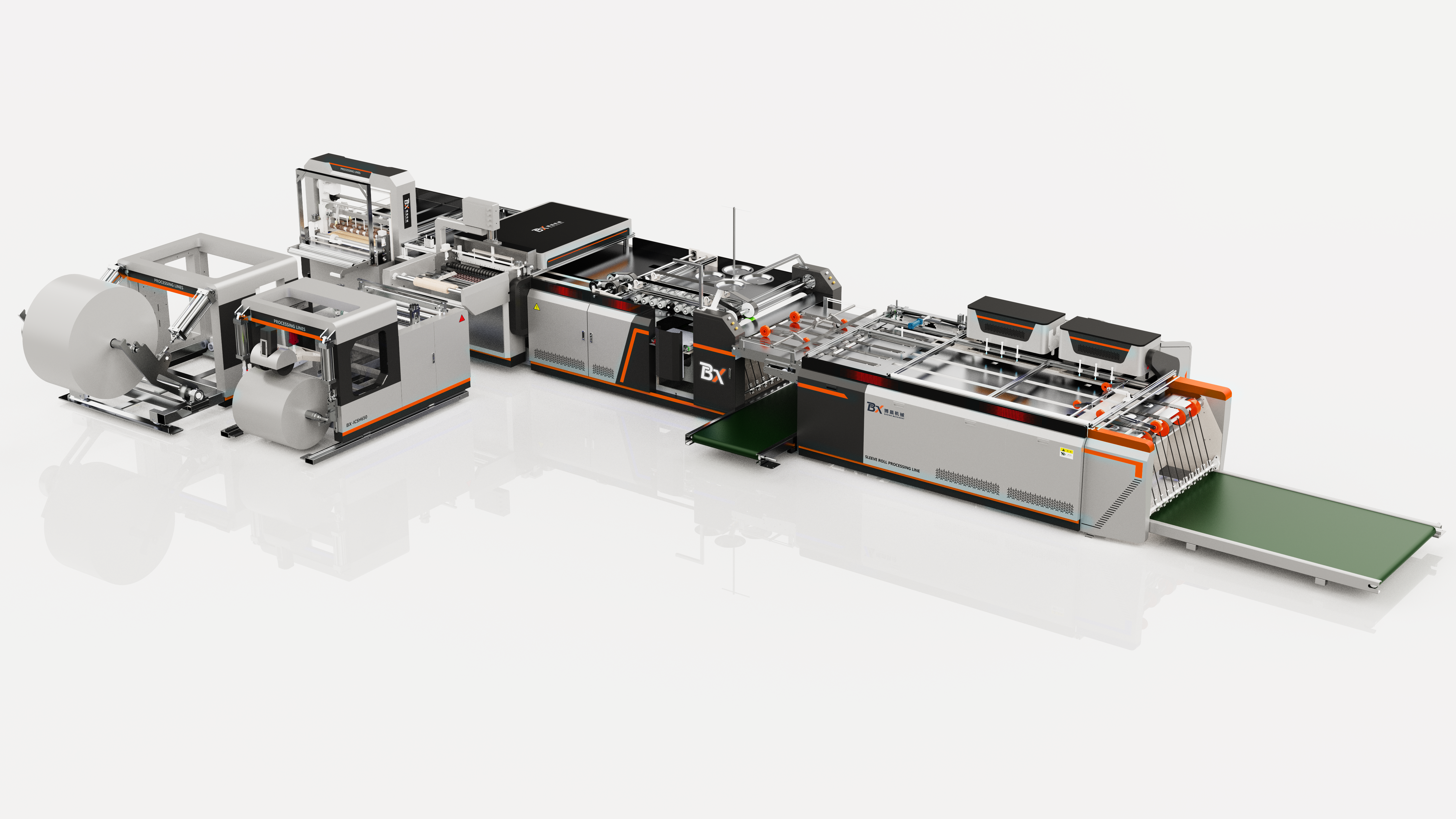

Woven bags have a wide range of applications. They are commonly used for packaging fertilizers, animal feed, grains, chemical raw materials, as well as for products like cement and building materials. The woven bag cutting, sewing, and hemming all-in-one machine is a crucial terminal equipment in the production process. It integrates three process - cutting, sewing the bottom, and hemming (folding the edge) – enabling fully automated production from tubular fabric to the finished bag. This equipment greatly boosts production efficiency, stabilizes product quality, and is an indispensable automation asset for modern woven bag factories.

As a fundamental industrial product, the woven bag reflects the capability of the equipment manufacturing sector behind it. The continuously rising technical requirements for woven bags are further driving the technological upgrade and sustainable development of the entire industry.

Post time: Sep-26-2025